Visual Testing (VT)

Visual testing also known as visual inspection is one of the most common techniques which involves the operator looking at the test piece. This can be aided by the use of optical instruments such as magnifying glasses or computer-assisted systems (known as 'Remote Viewing').

This method allows for the detection of corrosion, misalignment, damage, cracks, and more. Visual testing is inherent in most other types of NDT as they will generally require an operator to look for defects.

Magnetic Flux Leakage (MFL)

Microwave Testing

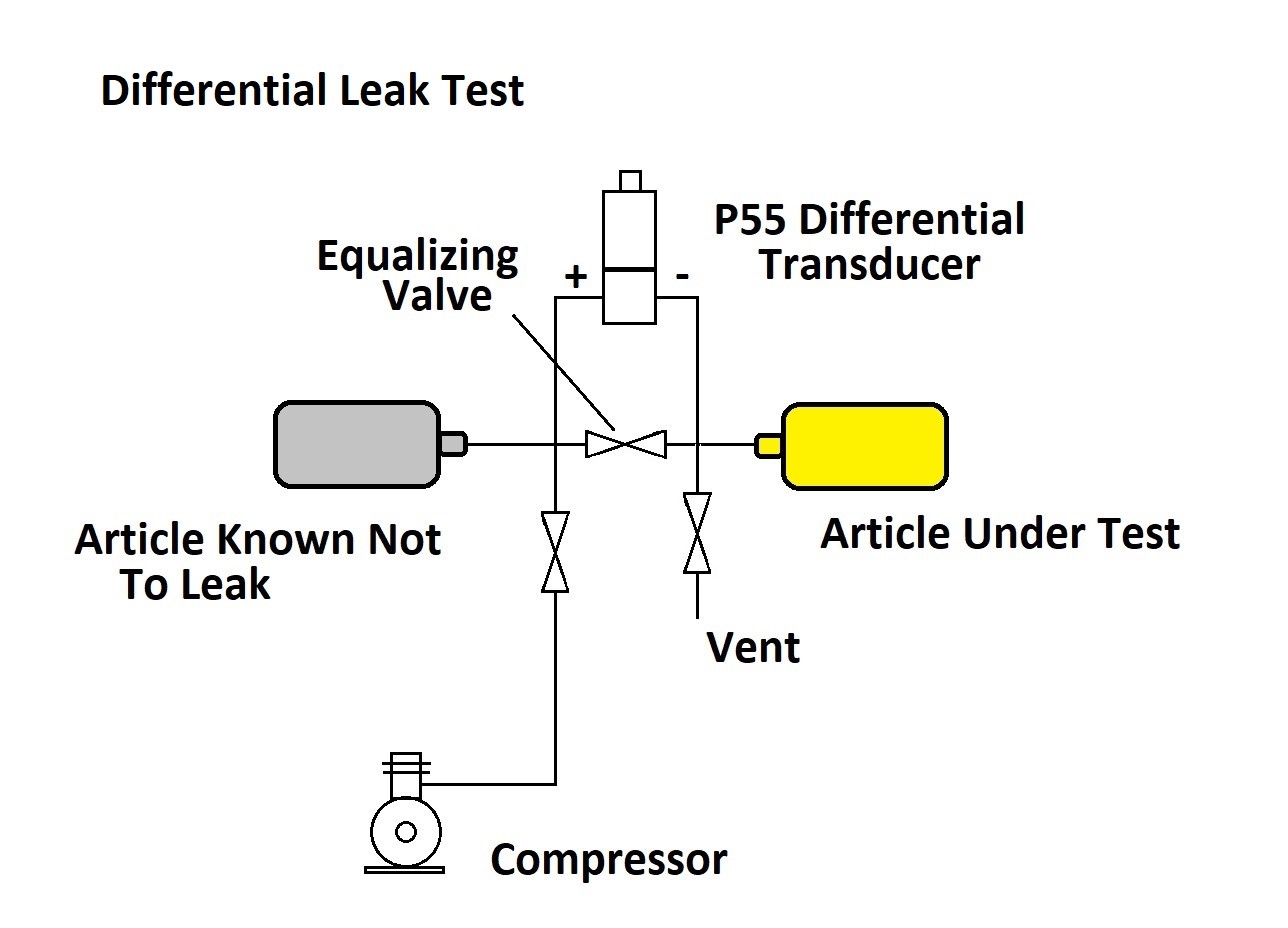

Leak Testing (LT)

Leak testing can be broken down into four different methods - bubble leak testing, pressure change testing, halogen diode testing and mass spectrometer testing.

Bubble leak testing uses a tank of liquid, or a soap solution for larger parts, to detect gas (usually air) leaking from the test piece in the form of bubbles.

Only used on closed systems, pressure change testing uses either pressure or a vacuum to monitor the test piece. A loss of pressure or vacuum over a set time span will show that there is a leak in the system.

Halogen diode testing also uses pressure to find leaks, except in this case air and a halogen-based tracer gas are mixed together and a halogen diode detection unit (or 'sniffer') is used to locate any leaks.

Mass spectrometer testing uses helium or a helium and air mix inside a test chamber with a 'sniffer' to detect any changes in the air sample, which would indicate a leak. Alternatively, a vacuum can be used, in which case the mass spectrometer will sample the vacuum chamber to detect ionized helium, which will show that there has been a leak.